BURSTING DISCS

At Pmax Solutions, we are committed to providing the highest quality pressure relief solutions to the Australian market. We proudly distribute products from leading German manufacturers in the world of Pressure Relief Devices. Our expertise and comprehensive product range ensure that we can meet the unique needs of our clients across various industries.

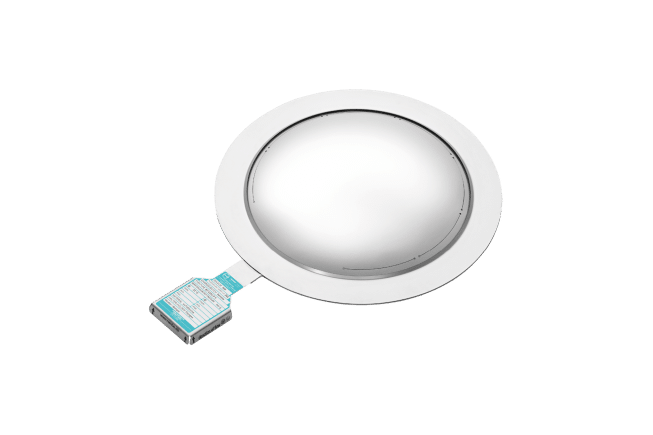

Today, we spotlight one of our essential product categories: Bursting Discs

What are bursting discs?

A bursting disc or rupture disc is a non-closing pressure relief device used to protect equipment such as pressure vessels, piping, gas cylinders, boilers, pumps, reactors or other enclosures from excessive pressure and excessive vacuum. Bursting discs and rupture discs are pressure relief devices activated by static differential pressure between inlet and outlet of the device. Bursting discs are used in single or multiple relief device installations.

These non-reclosing pressure relief devices are designed to burst at a predetermined pressure, providing a reliable and immediate response to over-pressure scenarios. Bursting discs respond very quickly to pressure and can be used to implement pressure relief in many different applications. Bursting discs or otherwise known as rupture discs are manufactured according to EN ISO 4126, AS 1358-2004, AD Merkblatt A1 and ASME BPVC VIII.

Bursting discs manufactured in the USA are known as Rupture Disks or Rupture Discs. Rupture discs manufactured in Europe are known as Bursting discs. Bursting discs can be installed directly onto pressure vessels and pipes as the primary safety device, or they can be installed with safety valves as the secondary safety device.

Bursting discs can also be installed in combination with safety valves for example directly underneath the safety valve to protect safety valves from corrosive applications. Bursting discs are a good alternative to safety valves due to their light weight specially in sizes above DN40 or 1.5 inches.

Bursting discs do not require annual re-certification or annual testing unlike safety valves. Bursting discs are an economical solution compared to safety valves when they need to be manufactured in high alloy materials such as duplex, hastelloy, monel, Inconel and titanium.

Bursting discs are easily monitored with break wires or signal membranes which allows simple burst detection of the pressure relief device. This allows control rooms to easily monitor if a bursting disc has ruptured. They can be installed in hazardous or non-hazardous areas.

What should I be aware of when selecting bursting discs?

- The plant components to be protected

- Process medium: Gases, Fluids, Steam or 2-phase flows

- Operating pressure

- Pressure cycling or vacuum cycles

- Required burst pressure

- Operating temperature

- Size of bursting disc or required mass flow to be discharged

Meet our trusted manufacturer REMBE

REMBE GMbH

Renowned for their innovations and quality, Rembe bursting discs offer unparalleled performance and reliability. Manufacturing and testing are done at their state-of-the-art plant located in Brilon Germany, capabilities to produce bursting discs in sizes up to 56” and bursting pressures beyond 5000 Bar. With a range of products designed for different applications, Rembe ensures safety and efficiency in your operations.

Applications of Bursting Discs

- Food and Beverage: Pumps, Distilling, Boilers, Cookers, Storage Vessels, Compressed Gas and sanitary liquid processes.

- Chemical Plants: Reactors, pipes, storage vessels, safety valve protection, road and rail tanks and heat exchanges

- Power Generation: Protecting boilers and turbines from pressure anomalies

- Pharmaceutical: Nitrogen tanks, batch reactors, biotech, centrifuges, separation vessels and sterilizing vessels.

- Mining: Pumps and Piping, Slurry Lines, leaching and extracting and Elusion columns, dewatering systems.

- Breweries and Wineries: Fermentation and Storage Vessels, C02 Storage.

- Paint Manufactures: Reactors and Mixes, Safety Valve Protection.

- Lithium Batteries: Housing Protection and Container Over Pressure Protection

- Oil and Gas: Flares, Gas Turbines, Heat Exchanges, Pipes and Storage Vessels.

- Pulp and Paper: Steam Drums and Boilers, Steam Auxiliary Systems.

- Desalination Plants: Filters, Pumps, Tanks and Pressure Vessels.

- Safety Valve Isolation and Protection: Corrosive Applications & Crystallization fluids. Ensuring Safety Valves are leak free.

Benefit of using REMBE Bursting Discs

- Reliability: Immediate and precise pressure relief. Rupture discs open in milliseconds.

- Safety: Protects both equipment and personnel.

- Cost Effective: Reduces the need for complex maintenance and inspection routines.

- Versatility: Suitable for a wide range of applications and industries

- Compliance: Meets stringent international and Australian standards

- Limited down time: 24-hour rush order manufacturing.

- Environment: Protects the environment from harmful gases because bursting discs are 100% leak free installations.

- Full Bore Opening: The entire cross section is used for fast and safe pressure relief.

- High Quality: Precision manufacturing and Testing in Brilon Germany