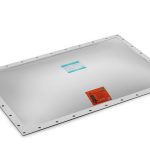

EXPLOSION VENTS

Pmax Solutions is your trusted partner for Explosion Safety. We provide reliable and cost-effective explosion venting and isolation systems. This includes explosion vent panels, flameless explosion vents and explosion isolation valves suitable for a wide range of applications.

Our products are just not excellent, they are proven and certified. Manufacturing and testing are exclusively done in Brilon Germany providing our clients with the highest quality needed to ensure the safety of plant equipment, personnel and the environment.

What are explosion vents?

Explosion vents are pressure safety relief devices to protect equipment and buildings handling combustible dusts. Explosion vents are also known as rupture panels, explosion vent panels, and flameless explosion vents.

Explosion vents are used to protect equipment from dust explosions that can occur inside silos, hoppers, tanks, dust collectors, filters, bucket elevators, grinders and milling machines. Explosion vents are manufactured according to ATEX, NFPA EN16009 and EN14797:2006 standards.

Explosion vents are essential safety devices for manufacturing plants handling combustible dusts in hazardous zones 20, 21 and 22. Explosion vent panels are generally used for outside applications and flameless explosion vents can be used for indoor and outdoor installations.

Flameless explosion vents trap flames rapidly and efficiently inside a stainless-steel mesh filter which cools and extinguishes the flames down immediately. No flames and no pressure waves exit the vessel. Explosion vents are available with monitoring switches or break wires to detect rupturing or opening.

These monitoring devices are used to shutdown processes immediately after an explosion. Guidance in Australia is covered by the Australian standard AS4745:2004 Code of Practice for handling combustible dusts.

Benefits of using REMBE Explosion Vents

- Hygienic designs manufactured in accordance with EHEDG – European Hygienic Engineering and Design Group

- Hygienic designs protect against cross-contamination and enables CIP cleaning

- Sanitary designs with USDA approval

- All products are identified with batch serial numbers allowing for exact reproduction

- Manufactured and tested in Brilon Germany

- Maintenance free and exceptionally long service life

- Simple and easy to install

- Independently verified leak-tight integrity

- Provides stability at pressure cycling conditions

- Low response pressure with full vacuum resistance is available

- Customised shapes for example round, square, rectangular and trapezium

- Local stock in Australia provides fast delivery

Our trusted manufacturer REMBE

REMBE GmbH

With over 45 years of experience, REMBE is the world leader of dust explosion safety. Their expertise provides the best possible protection for your systems and processes. REMBE’s products are manufactured according to the latest up-to-date international standards for management systems, pressure equipment and explosion safety devices. As well as prioritising quality and reliability, REMBE attach major importance to eco-friendly technologies, manufacturing processes and compliance with standards. High quality materials from controlled sources ensure that manufactured products have exceptionally long lifetimes.

Applications for Explosion Vents

- Filters and Dust Collectors handling combustible dusts

- Silos storing food powders for example sugar, flour, malt, milk powders

- Silos storing coal, wood chips and sawdust

- Spray Dryers, Cyclones and fluidbed dryers in the food manufacturing industries

- Bucket Elevators handling combustible bulk materials for example grain, malts & sugar

- Starch dryers, screens, sieves and ovens

- Pressure vessels in the pharmaceutical, chemical and food industries

- Protection of Mills, Milling Machines and Grinders

If you would like to know more about Explosion Vents please click on the below links for full PDF document: